Lower Embodied Emission

Smaller & Lighter

Less Rare Earth Magnets

Cheaper

More Power

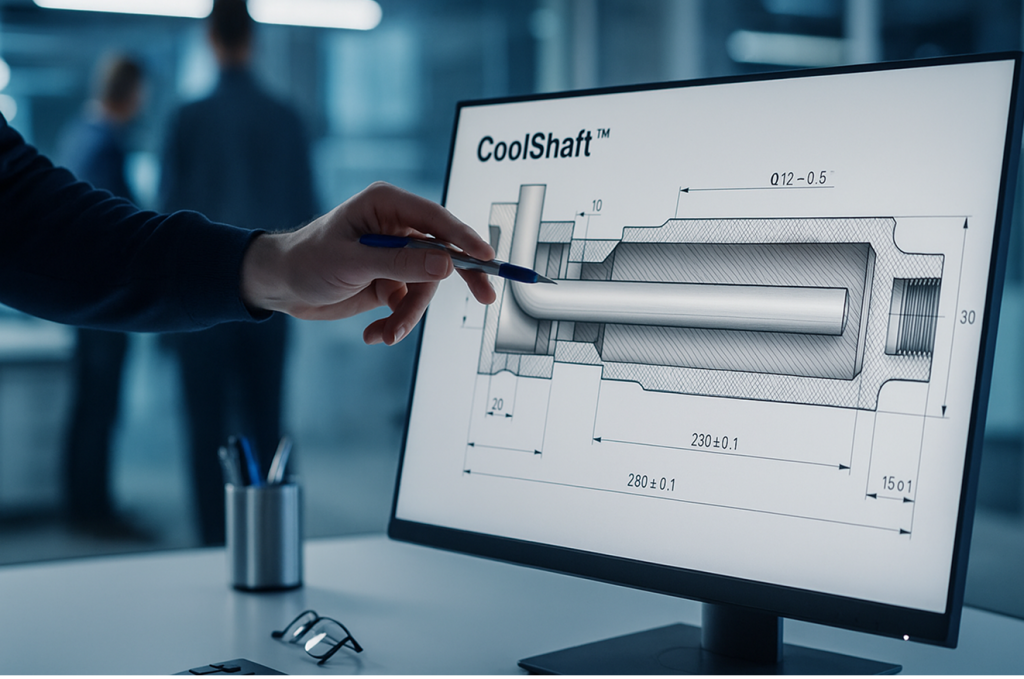

Built to cool, Engineered to Lead

cost reduction

Electric motors drive the future of mobility, but they are fundamentally constrained by heat buildup, the thermodynamic barrier.

Rotor heating is often the fundamental bottle neck that controls the size and cost of conventional motors (95% of motors). Rotor heat control is also the key that enables the adoption of the ultra cheap, ultra clean magnet less motors.

CoolShaft™ is a breakthrough rotor cooling system that removes this bottleneck. Designed to integrate seamlessly into existing electric motor architectures, CoolShaft™ can enable more than 50% more continuous power, which can be converted to 50% smaller and lighter motors, & unlocks the adoption of magnet less motor topologies. These are all without the need for a clean-sheet redesign.

Electric machines have come a long way in terms of efficiency and compactness, but one challenge persists is cooling.

Today’s motors are sized not by their electromagnetic performance, their sizing depends on their inability to dissipate heat, where often the rotor heat is the limiting factor. This leads to oversized motors, excessive use of rare-earth magnets, and limited efficiency under real-world driving conditions. These issues persist at various degrees in all motor topologies.

Motor market & CoolShaft application

Rotor overheating limits continuous power and continuous power is the most important aspect of a motor’s performance. That is why established, leading motor manufacturers quote the performance of their motors using continuous power.

Continuous power is the real measure of a motor’s capability. It defines how much power a motor can deliver over time, during sustained highway driving and freight hauling

Unlike peak power, which lasts seconds, continuous power defines the motor’s true utility in real-world conditions.

This is why motors today are oversized, overbuilt, and over-dependent on expensive rare-earth magnets. It is not because they need more torque, but because they can’t stay cool enough for long enough.

At Cooled Motors, we focused on the real problem, how to unlock continuous power by cooling the rotor.

Delivering more continuous power requires the removal of the heat build-up, and today’s cooling strategies aren’t up to the task. While stators are commonly cooled with water jackets, rotors are left to passively shed heat through conduction and ambient airflow which is an inherently inefficient process, especially at high RPMs. This is due to the air gap between the rotor and the stator (rotor needs to be free to spin) acting like insulation.

At Cooled Motors, we believe the future isn’t about chasing attention-grabbing peak power figures it’s about delivering reliable, repeatable, high-performance continuous power. That’s why we built CoolShaft™ a rotor-first cooling system that enables smaller, more efficient, and more sustainable motors without the PR fluff.

This is the most common thermal management method which wraps the stator in a liquid-cooled jacket. Almost all motors use this method which works well to cool the stator.

Pros: Highly effective for cooling the motor at low speeds (below the base speed), hence enhance the peak torque at low speeds.

Cons: has negligible cooling effect on the rotor. The rotor temperature is the critical limit for continuous power, magnet grade, size and cost.

To address rotor heat, some up and coming designs have tried to use Automatic Transmission Fluid (ATF) oil to cool the shaft or sprayed onto end windings. This improves contact and avoids electrical conductivity risks. But there are significant trade-offs:

Pros: Oil as a fluid is easy to understand and handle by the electric industry. It’s a low hanging fruit that doesn’t bare much

Cons: Oil systems are complex, expensive, & underperform, making them commercially unattractive.

50:50 Water-ethylene glycol (50/50WEG) is the standard cooling fluid used in all EVs. Water based shaft cooling offers dramatically better thermal performance, but only if you can contain it.

CoolShaft™ is the first complete water-based rotor cooling system that’s leak-proof, automotive-grade, scalable and production-ready. Unlike simplistic hollow-shaft oil-cooling attempts, CoolShaft™ is a fully engineered system combining, Advanced multi-layer sealing, leak-proof under continuous high-speed rotation, aerospace-grade CFD-optimised flow paths for maximum cooling with minimal pressure loss, cross-industry expertise from oil & gas, aerospace, & automotive

Removing rotor heat is the heart of the continuous power limitation. With CoolShaft™ you can have:

CoolShaft™ doesn’t just cool better. It solves the single biggest limitation in every electric vehicle motor today.

We have tested the CoolShaftTM design with 20+ motor designs that are currently in vehicles in the market using industry standard multi-physics simulations with the following results:

When retrofitted with CoolShaft™, the i3 motor unlocked significant extra continuous power. The increase averaged around 30% around the ‘Zone of Interest’ (3000rpm to 8000rpm) and about 240% in the high-speed region above 8000rpm. The rotor temperature dropped from an average of 130°C to 90°C, allowing for the magnet grade to be reduced by 2 grades. This in turns reduces the reliance on , one of the rarest of the rare earths.

The BMW i3’s stator temperature limit of 170 °C became the limiting factor with the CoolShaftTM.

This demonstrates how rotor thermal limitations, not electromagnetic constraints, are the true barrier to sustained motor performance.

We have tested the CoolShaftTM design with 20+ motor designs that are currently in vehicles in the market using industry standard multi-physics simulations with the following results:

This is how a 50% smaller motor translates into a vehicle-level transformation — one that improves performance, efficiency, and manufacturing flexibility all at once. CoolShaft™ makes this possible by unlocking thermal headroom and eliminating the need to over-engineer motor volume for heat.

A Key Enabler for Magnetless Motors

CoolShaft™ is designed for fast adoption and global deployment.

80%+ parts are common across different motor products

Integrates into 95% of existing & future motor architectures

No need for retooling. Compatible with standard casting and machining

CoolShaftTM goes beyond traction motors in passenger electric vehicles, CoolShaft™ is ideal for any electric machine limited by rotor heat

Reduced costs, increased performance, smaller, lighter motors

Enables motor downsizing to fit existing engine bay constraints – hybrid without platform redesign

50% more power using the same motor

Reduce the wight and Size of Motors from air taxis and large drone – dual application

More power or downsized motor for lower cost and more payload capacity

Liquid cooled motors for maximum performance, compactness and reduced costs.

More compact, higher efficiency, cheaper generators using the CoolShaftTM technology.

By cooling the rotor, we unlock:

& a clear path toward next-generation, magnet-free electric motors